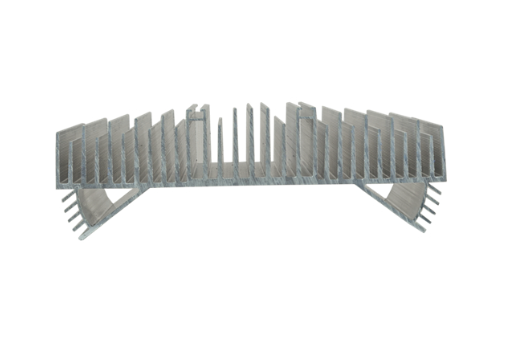

Copper or Aluminum Heatsink: Which Is Better?

Heat sinks are some of the most important critical components of modern electronics. They are designed to keep electrical systems cool and protect them from overheating in the course of their functions by absorbing and dissipating heat. With that said many people wonder what would be the most effective, pocket friendly and overall superior material for heat sinks, with the debate focusing between copper and aluminum.

In this post we will try and settle this question by highlighting the qualities we look for in good heatsinks and how well these two metals measure up.

Let’s dive right in.

1. Weight

When producing electrical components on a mass scale, weight becomes a critical factor to consider. At equal volumes aluminum is one of the lightest industrial metals in the world today making it far superior to alternatives such as copper in this regard. Choosing a lighter metal makes it easier to transport and handle the components in question significantly hence cutting down your overhead costs.

2. Surface Coloration

If aesthetic considerations will factor into your selection criteria, then aluminum will be your best bet. It is possible to anodize aluminum thereby altering its color to suit your individual tastes and preferences which cannot be done with copper.

3. Cost Effectiveness

Budget considerations are at the forefront of most if not all manufacturing decisions and this applies in the realm of heatsinks at the same time. Pound for pound aluminum is considerably cheaper as compared to copper.

This alone makes it much more appealing for manufacturers building electronics that will be used in different systems. Compared to copper, aluminum is the more viable option for those trying to balance functionality with budgetary constraints.

4. Thermal Conductivity

The work of a heatsink is to absorb excess heat and transfer it away from the working components of an electrical system. For a need to do this then the metal in question needs to have a high thermal conductivity. Here copper outperforms aluminum thanks to its essential composition which allows for faster heat transmission.

5. Availability

Copper is widely used in various components aside from heatsinks. You will find copper used in wiring networks, scientific instruments and also in sensitive instruments. When we combine the wide and various uses of copper and the limited supply of metal available to us then it becomes clear that aluminum will be much easier to source or acquire.

Aluminum is one of the most common, widespread and easily accessed metal in the world making it incredibly convenient. These conditions make aluminum easier to and cheaper to acquire.

6. Corrosion Resistance

When exposed to the elements, aluminum will react with oxygen to form an aluminum oxide layer that protects it from the potential damage of rust and corrosion. This natural protection serves to strengthen and protect it under the most severe conditions.

Copper will also form a patina when exposed but this layer will only serve to change its coloration without adding to its inherent durability.

7. Magneticism

Electrical appliances and machines are prone to generating electromagnetic fields due to the action of electric currents and the components they comprise need to be resistant to them. Copper and aluminum are both nonmagnetic which makes them equally immune to this potential risk.

8. Recyclability

Global consciousness has shifted to make us all concerned about the state of our environment and the eco friendliness of the items we use and consume. Aluminum and copper are both considered valuable metals that should be recycled and placed for other uses once their initial work purpose is rendered obsolete.

In the recycling world aluminum is easier to repurpose thanks to its versatility and minimal purity requirements making it more appealing from a strictly ecofriendly standpoint.

9. Malleability

The plasticity of a metal refers to its tensile strength, ductility as well as yield strength. These factors determine its ability to be shaped and molded into the shapes we desire which is a crucial consideration because of the intricate shapes heatsinks take.

Aluminum is incredibly malleable and capable of taking any complex pattern we require although copper is softer and more malleable.

Final Thoughts

Heatsinks play a vital role in modern electronic systems such as computers, LED light setups, household appliances and general electronics of all kinds. When making a comparison of the options available to us then aluminum heatsinks emerge as a superior option mainly due to two essential factors - that is cost and weight.

However, it’s good for us to be sure that we have the best components to ensure a better performance. For all your aluminum needs then make Weiye Aluminium your first choice.