Contact

OEM/ODM Extruded Aluminum Louver Profile

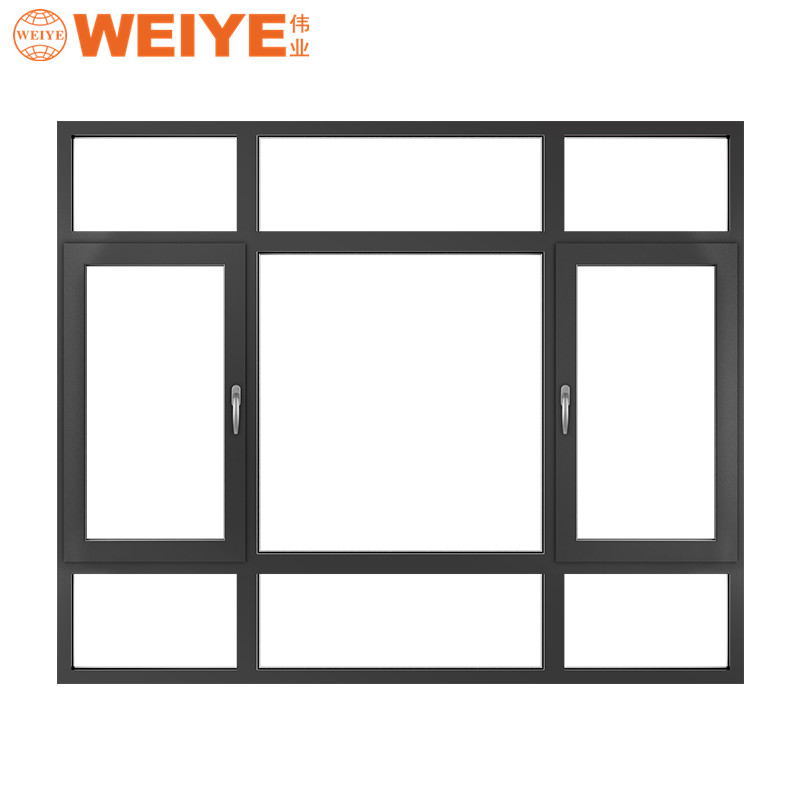

Wholesale Thermal Break Aluminum Casement Window Profile

Custom Aluminum Handrail System Profiles

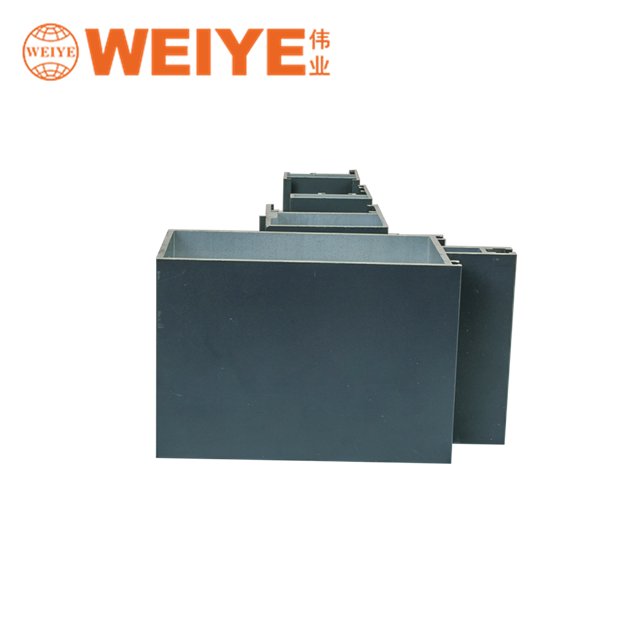

Aluminum Formwork System Profile

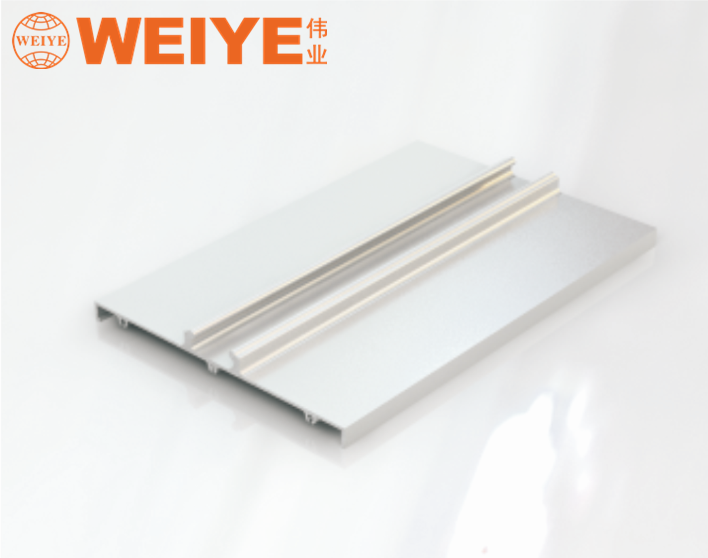

Wholesale Aluminum Curtain Wall Profiles

Aluminum Casement Window Frame Extrusion Profile

OEM Aluminum Extrusion Decoration Profile for LED Light Strips

China Wholesale Waterproofing Aluminum Profile for Light Decoration

Custom-made Durable Aluminum Decoration Profile Channel for LED Lighting Industry

Wholesale High-quality Aluminum Handrail & Railing Profile

High Quality Custom Thermal Break Aluminum Casement Window Profile

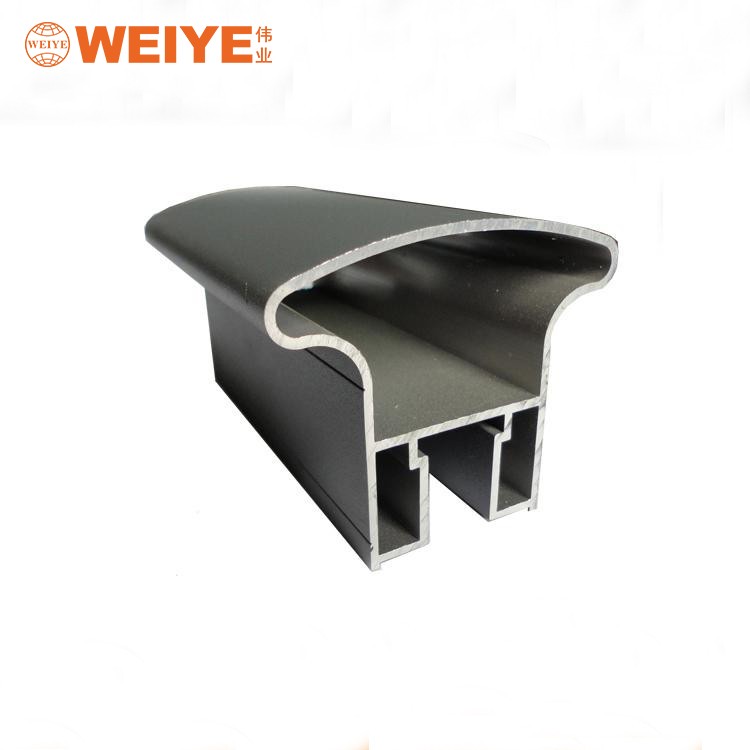

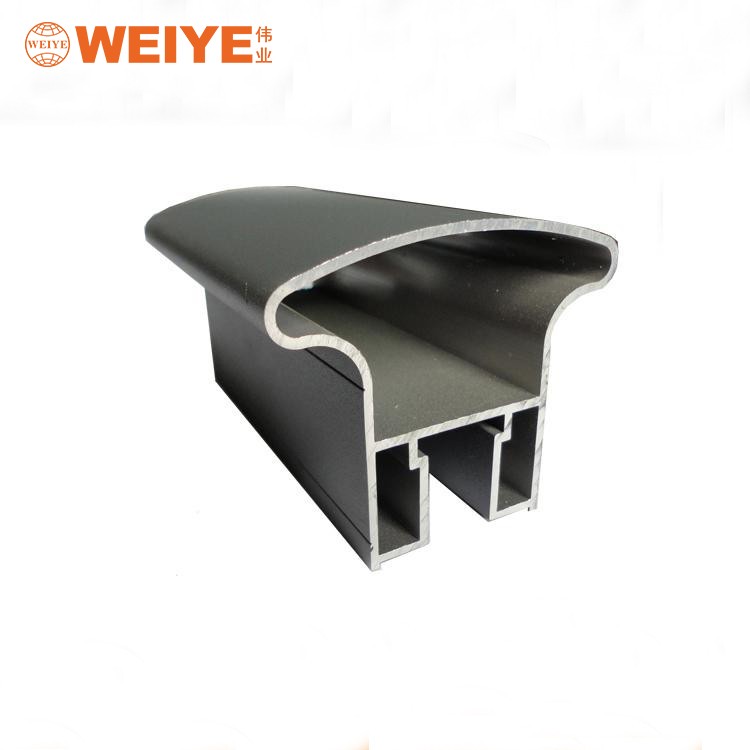

Custom Extruded Aluminum Cap Rail System

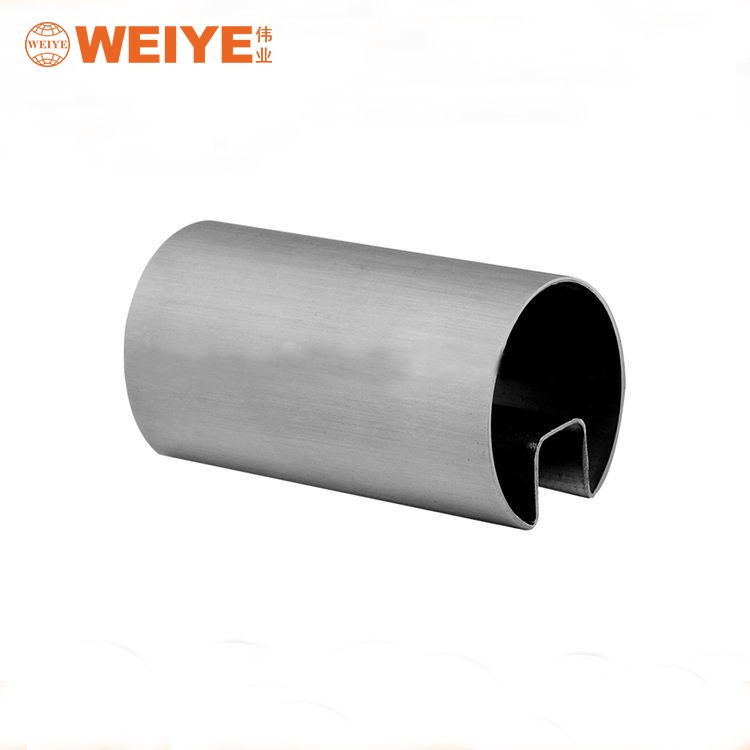

OEM Aluminum Pipe Railing Extruded Handrail Profile

China Custom Aluminum Casement Window Profile

Casement Window Aluminum Profile

Double Casement Window Aluminum Profile

China Custom Extruded Aluminum Profile for Curtain Wall System

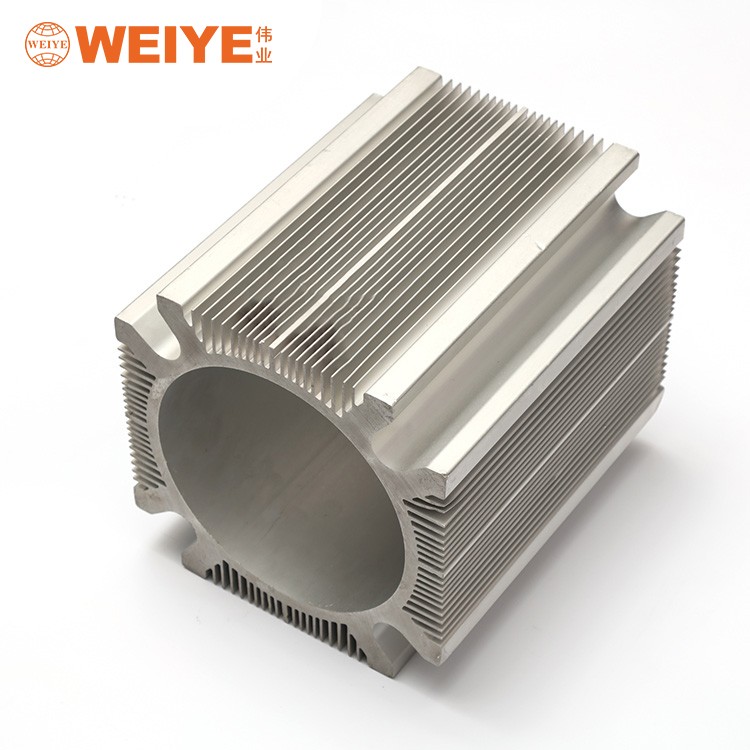

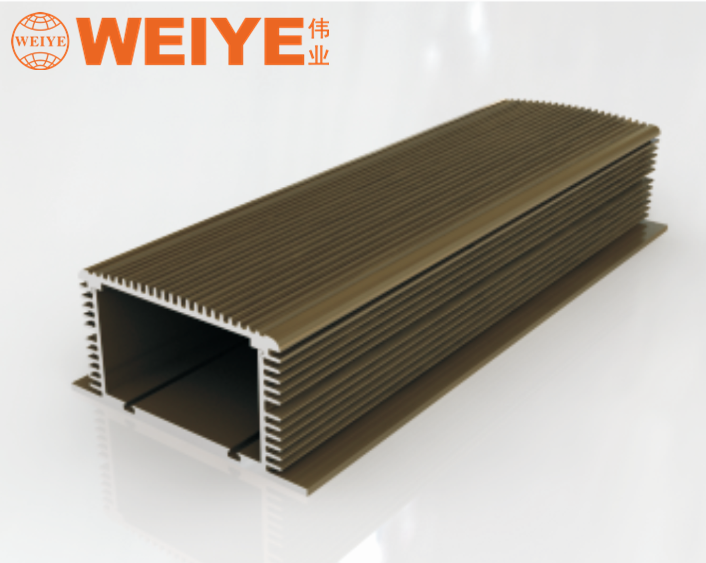

Aluminum Profiles for Motor Shell

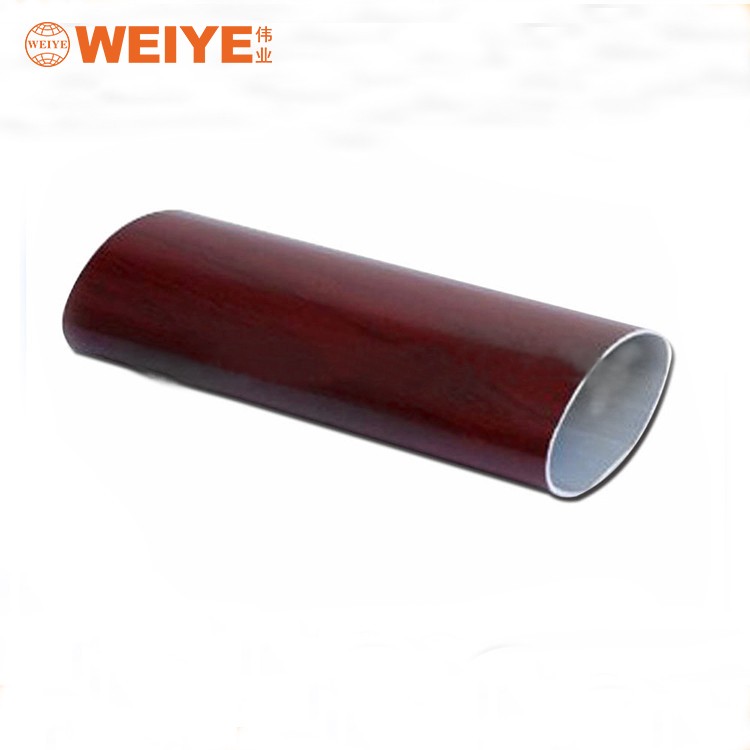

Custom Aluminum Extrusion Motor Body

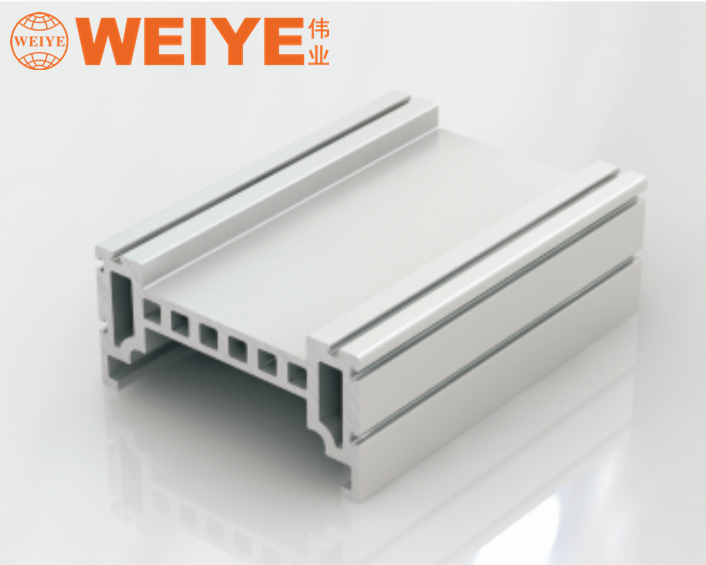

Aluminum Profiles for Mechanical Accessories

Many industries in the market need aluminum extrusion products, which has opened the market to many different opportunities. Whether you are going for the aluminum extrusion profile or simply choosing the final item, you can rest assured that you will find it with us. At Weiye, we have dedicated time and resources to aluminum products and ensure your needs will be met.

We cater to different industries in the market and always ensure you have high-quality yet affordable aluminum profiles for different uses, including aluminum windows and doors, curtain walls, formwork systems, solar panel aluminum frames, etc. Our profiles are sturdy and lightweight and can be produced in record time. We have worked with different industries in the past, and they all have stellar reviews regarding the services they receive.

Weiye Aluminium is committed to quality, and we ensure that no matter the size or complexity of your order, we will always deliver. If you are in the market looking for a reliable aluminum profile supplier, then reach out to us. We will guide you on what you need and how many pieces to order that will be perfect for your production or project.

If care is not taken, your aluminum extrusion will return with certain defects. Here are the common types and how you can prevent them.

Aluminumprofile bumps. These bumps are caused by improper protection measures onthe metal and carelessness during extrusion. One way to solve it is toensure care is taken during extrusion. Abrasionon the profile. Worn-out molds and dirt cause abrasion on the extrusioncylinder. Ensuring no debris on the mold and extrusion cylinder will go along way to resolving the issue. Diemarks on the extrusion. Another thing you will notice is die marks on thefinal extrusion. These often look uneven throughout the extrusion and messwith the dimension of the final extrusion profile. Die marks occur whenthe mold surface has debris or sharp corners. To help resolve this, themold surface must be cleaned after every extrusion. The working beltshould also be well-designed to ensure the extrusion process is smooththroughout. Twisting,bending, or waves on the extrusion. All these occur when the design of thedie-holes is not well carved out. Ensure you make the molds in the rightdimensions before extrusion.

Aluminum extrusion does not contain lead; however, if you choose to use an alloy made up of metal in the same family as lead, you might get trace amounts in the final piece. Since lead is considered unsafe, research the alloy you want to use for your extrusion. Doing so will go a long way in ensuring you know the components of the final extrusion. It also helps you figure out if the alloy used is safe for whatever you need the extrusion is used for.

Tolerances for extruded materials are around 0.5mm. We can get lesser tolerances without machines, which is handy when you need the final pieces to be uniform.